WEAR RESISTANT systems by Kingfisher Industrial

Solutions for handling bulk solid materials

Wear Resistant Linings

Working closely with preferred material partners, Kingfisher offers an unbiased approach to solving the problems experienced when handling bulk solid materials.

Despite manufacturers’ many claims to offer the ultimate material in the ‘fight against wear’, success levels vary from extremely good to extremely poor. Sometimes the wear-resistant properties of one material type may be in excess of requirements and conversely, those same properties may under-perform in a different application, putting the material’s suitability in either case under question.

For wear protection, three familiar material groups – ceramic, metallic and polymer – are commonly marketed with all economically-produced materials belonging to one group or another and all playing a part in protecting plant and equipment from plant degradation.

Kingfisher offer solutions for all three material groups but carefully tailor our solution to each specific problem.

Wear resistance material groups

In undertaking a full in-depth analysis of the plant’s operational criteria, we will identify a system that is fit-for-purpose to meet the many requirements of the end user. Whether these are driven by budget, operation, safety or other plant criteria, such individual requirements justify our unique approach to solving their inherent problems.

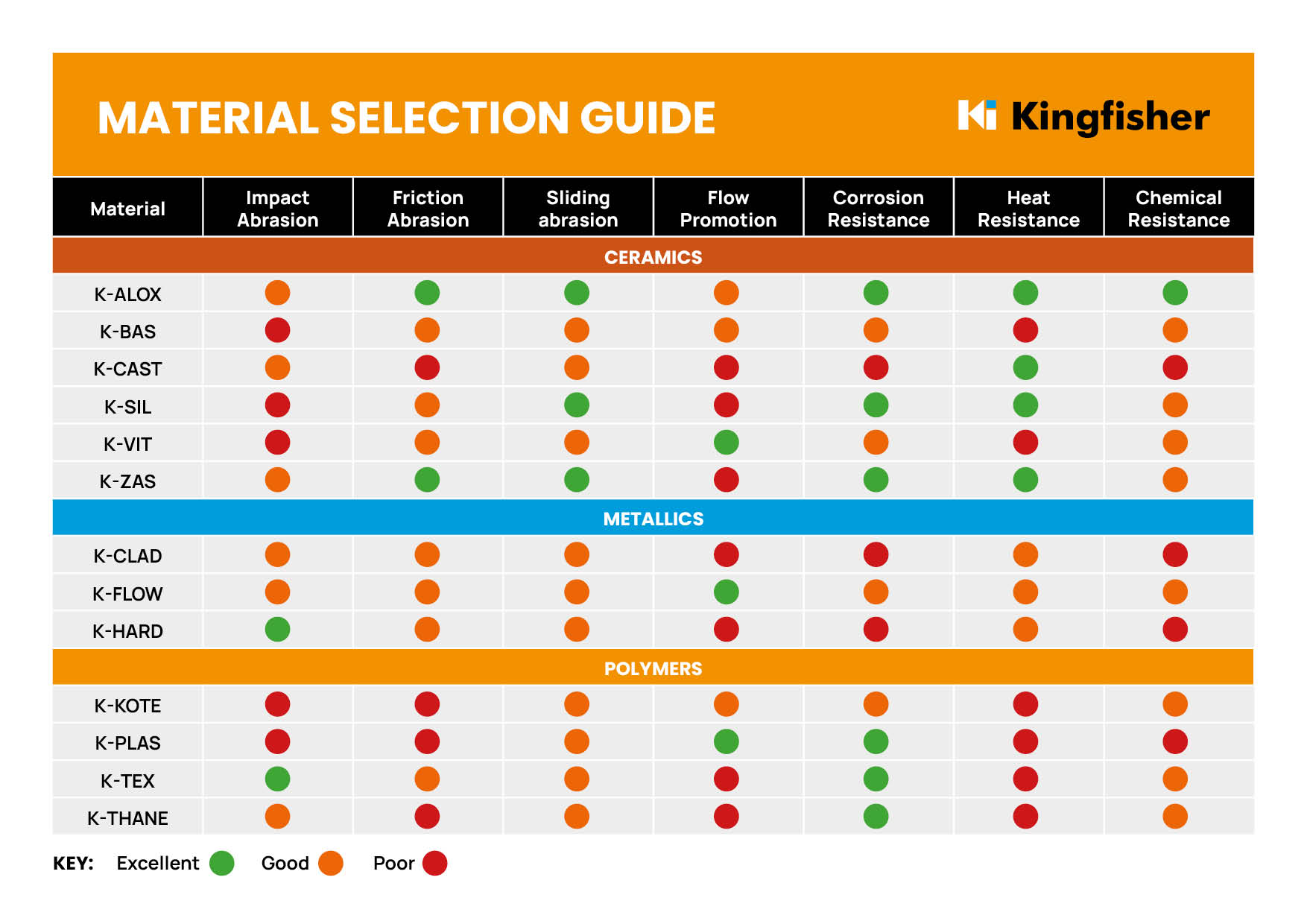

Browsing our materials selection guide gives you a broad perspective of the usage range against the operational criteria of each application.

Ceramics

Metallics

Polymers

MATERIAL GROUP SELECTION GUIDE

In support of industry needs, our service offering consists of a package of design, manufacture, protection and site installation of process plant equipment undertaking all activities in house utilising our fully trained and qualified personnel and resource facilities which reduces the risk of a breakdown in the supply chain. Performing to international standards of best practice with regard to quality control, environmental and health & safety, we align ourselves to the expectations of our valued customer base of internationally recognised OEMs, EPC contractors and end users many of whom are PLC’s operating on a global basis.

Our Services

In support of industry needs, our service offering consists of a package of design, manufacture, protection and site installation of process plant equipment undertaking all activities in house utilising our fully trained and qualified personnel and resource facilities which reduces the risk of a breakdown in the supply chain. Performing to international standards of best practice with regard to quality control, environmental and health & safety, we align ourselves to the expectations of our valued customer base of internationally recognised OEMs, EPC contractors and end users many of whom are PLC’s operating on a global basis.

design

Our engineers enthusiastically embrace the development of new design criteria and software, exploiting these tools to create new design and manufacturing concepts

Manufacture

Our UK manufacturing facility gives us an enhanced capability to handle equipment that most local engineering service providers would find too difficult.

Installation

Our location in the industrial heartland of the UK together with our overseas partnerships ensures that we can respond to the challenges associated with process plant and equipment.